Why Membranes are Popular for Biogas?

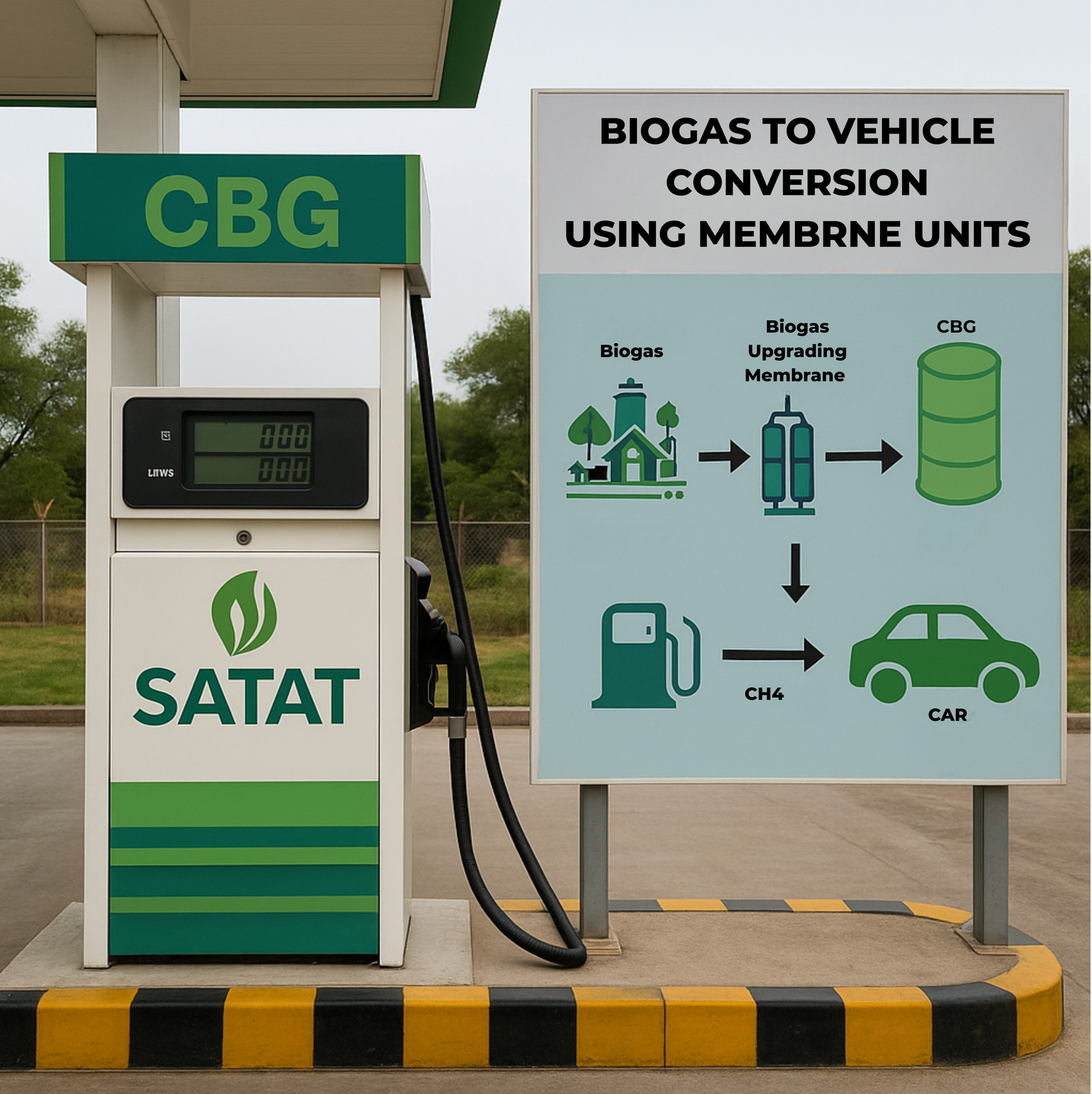

As the world moves toward cleaner and more sustainable energy sources, biogas is increasingly being seen as a powerful tool for reducing dependence on fossil fuels. India, in particular, is investing heavily in biogas production and upgrading through government initiatives like SATAT (Sustainable Alternative Towards Affordable Transportation) and the support of the Ministry of New and Renewable Energy (MNRE).

But not all biogas is created equal. Raw biogas must be upgraded to remove impurities like carbon dioxide (CO₂), moisture, and hydrogen sulfide (H₂S) before it becomes suitable for use as fuel. Among the various upgrading technologies, membrane-based systems are rapidly becoming the preferred choice for their energy efficiency, low operational cost, and scalability.

Understanding Biogas and the Need for Upgrading

Raw biogas, generated through anaerobic digestion of organic matter, typically contains:

50–70% Methane (CH₄)

30–50% Carbon Dioxide (CO₂)

Traces of Hydrogen Sulfide (H₂S), water vapor, and other gases

While this gas can be used directly for heating or electricity generation, it must be upgraded to at least 90% methane to be viable for vehicle fuel or natural gas grid injection. This is where upgrading systems come into play

2. Why Membrane Technology?

Membrane biogas upgrading works on the principle of selective gas permeation—methane passes through the membrane at a different rate than CO₂ and other gases. This allows effective separation without the need for chemicals or water.

Key Advantages of Membrane-Based Systems:

Energy Efficiency

No Chemicals or Water

Modular and Scalable

Compact Footprint

Diagram of a multi-stage membrane separation system

3. Membranes and India’s SATAT Initiative

Launched by the Government of India, the SATAT (Sustainable Alternative Towards Affordable Transportation) initiative promotes the production of Compressed Biogas (CBG) as a clean fuel alternative for transport.

The target:

Set up 5,000 CBG plants

Produce 15 million tonnes of CBG per year

Encourage private investment in biogas production

Membrane systems are critical to meeting SATAT goals because they help produce CBG that meets BIS standards for methane content (≥ 90%)—making it fit for vehicular use.

4. MNRE Support and the Future of Biogas in India

The Ministry of New and Renewable Energy (MNRE) has recognized biogas as a cornerstone in India’s transition to a green economy. Through subsidies, technical guidelines, and collaboration with oil marketing companies (OMCs), MNRE is actively driving:

Off-grid biogas generation

Biogas purification and bottling projects

Waste-to-energy policies

Membrane technology aligns perfectly with MNRE's goals due to its adaptability to different biogas sources—be it from agricultural waste, dairy farms, food processing units, or sewage treatment plants.

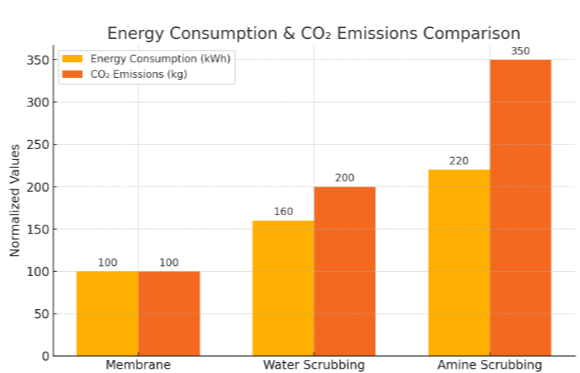

5. Energy Efficiency and Environmental Impact

Energy Efficiency and Environmental Impact

Energy efficiency is one of the biggest reasons why industries and municipalities are choosing membrane systems. Compared to energy-intensive chemical scrubbing, membrane-based separation systems:

Require less electricity

Produce no wastewater

Avoid toxic chemical handling

Offer long-term stability with proper maintenance

By reducing operational energy demand, these systems also lower carbon emissions, making the entire biogas-to-energy chain more sustainable.

6. The Global Trend Meets Local Potential

Countries like Germany, Sweden, and the U.S. have already adopted membranes in large-scale biogas plants. In India, the growing adoption of smart, compact membrane skids is helping industries meet green energy mandates, reduce fuel costs, and tap into new revenue streams by selling CBG to OMCs.

From municipal corporations to agro-industries, the demand is growing. Membrane technology’s ability to fit into existing infrastructure and scale with demand makes it a future-proof solution.

7. Final Thoughts: Clean Energy Starts with Clean Upgrading

Membrane-based biogas upgrading is not just a technological upgrade—it’s a strategic investment in the future of clean energy. Whether you're a farmer, food processor, city municipality, or industrial player, choosing the right technology is key.

Membranes offer the efficiency, purity, and simplicity that modern energy systems demand—without the complexity of chemicals or high-water usage.

Need Help Choosing the Right Membrane System?

At Daltech, we offer advanced membrane solutions for biogas upgrading that are MNRE-compliant, SATAT-ready, and built for efficiency.

📧 Sales@daltech.in

📞 85880 48800

🌐 www.daltech.in

🔗 Explore Our Membrane Solutions